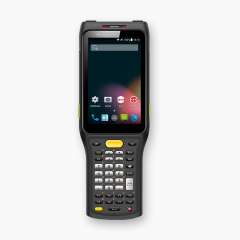

- Call up the system menu on the LogiScan-600/800/1100 (refer to corresponding FAQ).

- Call menu function Test→Code/RF-ID. "Barcode Test" is displayed in the title line.

- All barcode types activated in the scanner module can now be scanned. The corresponding barcode type is displayed.

The different barcode types differ in some cases substantially in terms of the character size, the information density, the max. Number of codable characters and security. While 1D barcodes can be read by almost all barcode readers (1D and 2D barcode scanners) 2D barcode scanners are required for 2D barcodes. All these characteristics and criteria must be taken into account when bar codes are to be used in a company.

Read more ...

If this barcode type is set and no further check is carried out (neither by the scanner nor by the application), a very high error rate must be expected. The following measures should be taken:

- If possible, use a check digit.

- Use a length fixation. That means, only barcodes with one or two lengths are accepted by the scanner.

- If there is a constant number of digits within the code, it should be checked by the application.

- 1D bar code scanners can only read 1D bar codes.

- 2D barcode scanners can read 1D and 2-D bar codes.

Read more ...

If the computer or the device which receives the data via the RS-232 interface can not process it as quickly as the connected device transmits it, the RS-232 interface must be operated with a handshake. This can be a hardware handshake (RTS/CTS, where the serial connection must contain these 2 signal lines) or a software handshake (XON/XOFF). The same type of handshake must be set on both communicating devices.

The prerequisite is that this computer supports USB/HID.

- Use the Serial HID Adapter.

- Deactivate the MTWin mode if this is set.

- Set the parameters of the RS-232 interface of the Serial HID Adapter to match the device to be connected.

- Connect the computer to the USB / HID interface of the Serial HID Adapter.

- On the computer, start the application to receive the data.

- Connect the device to the RS-232 interface of the Serial HID Adapter and start the data output.

- The Serial HID Adapter accepts the data and outputs it to the connected computer on the USB/HID interface.

If the battery has been inserted or replaced, the battery symbol in the status line (regardless of the actual charge state of the battery) always shows half the battery charge. Only after the charging electronics integrated in the device has determined that the battery was fully charged for the first time, the battery symbol corresponds to the charge level of the battery.

The prerequisite is that this computer supports USB/HID.

- Use the Serial HID Adapterand set the MTWin mode.

- Connect the computer to the USB/HID interface of the Serial HID Adapter.

- On the computer, start the application to receive the data.

- Connect the LogiScan-600/800/1100 to the RS-232 interface of the Serial HID Adapter.

- The Serial HID Adapter calls the data via the MTWin interface of the LogiScan-600/800/1100 and outputs it to the connected computer on the USB/HID interface.

Basically, the type of data transmission (cable-bound or GPRS) depends on the device hardware concerned and the application installed on the device.

Normally, nearly every application provides the cable-bound data transmission, which can be used on the PC by the freely available Windows software MTWin-5. Since the data interface of MTWin-5 is documented in the MTWin-5 manual and thus freely accessible, the data transfer function can also be integrated into customer-specific applications.

Devices with GPRS module, a SIM card and a corresponding application enable data transmission to an FTP server. The SIM card and FTP parameters must either be loaded via parameter table or set in the GPRS setup.

- Produce a hardware reset. "System Tests - DATABASE: wait ..." is displayed.

- Wait until "DATABASE: init." is displayed,

- Press the SHIFT key on the lower left of the keyboard,

- Wait until the system tests are complete.

- Press MENU to enter the system menu.

Make a software update with the file Defibrillator.mot (can be downloaded from the product page of the device). Then load your application.

Simultaneously pressing the following buttons with the device switched on:

- LogiScan-600: F1, F3 and 9

- LogiScan-800: 2, 5, and 7

- LogiScan-1100: F1, F4 and 9

Since the detected data are stored in the flash ROM, they are retained during a hardware reset.

When a LogiScan-600/800/1100 with RFID module is delivered, all transponder types are normally activated. If the transponder types in the RFID module are set by the application, a manual setting is not possible or will be overwritten by the next start of the application. If the transponder types are not set by the application, a manual configuration can be made as follows:

- Connect the LogiScan-600/800/1100 to the desired COM port of the PC.

- Call up the system menu on the LogiScan-600/800/1100 (see corresponding FAQ),

- Call the Admin→System menu function and press SHIFT 9,

- Select "RF-ID Port" and press ENTER,

- Com0 (this is the normal RS-232 interface, which is also used for data transmission) and press ENTER.

- Start the ACG Utility on the PC (can be downloaded from the product page).

- Select and connect the appropriate COM port.

- In the "Operation Mode" field, the desired transponder types can be activated / deactivated.

- Clicking the button "Apply Settings" writes the settings to the RFID module.

- Afterwards, the ACG Utility can be terminated and the application can be started on the LogiScan-600/800/1100.

- Call up the system menu on the LogiScan-600/800/1100 (see corresponding FAQ).

- Call the menu function Test→Code/RF-ID. "Barcode test" is displayed in the title line.

- Press SHIFT SCAN to switch to the RFID test. "Barcode test" is displayed in the title line.

- Now all transponder tags activated in the RFID module can be read. The corresponding transponder type is displayed.

Using the AutoHotkey Open Source software and a script, you can transfer the data received by MTWin-5 into any Windows application. The demonstration software AutoHotkey Demo for MTWin shows how to do that.

The transmission option can be selected for the receive file between "Collection File" (the data of all devices are collected in file MTWin.txt) and "Generation with Serial Number" (for each device a separate file is created).

Under Option→Directories, target directory and file name can be set for the received data. Different placeholders (for serial number, station number, date and time) can be used to generate the file name. In this way, it is possible to create a unique file name for each data transfer (detailed description contains the MTWin-5 manual).

A destination path given in the STX line at the beginning of the data transmitted by the mobile terminal replaces the destination path settings made in MTWin-5 and allows the transferred data to be stored in any different directories.

In order to be able to transfer data already transmitted, the data on the device may not be erased by MTWin-5 after the data transmission, but must only be marked as "already transmitted" (MTWin-5 function option> Transmission> after data reception> transmission Lock). For a new data transmission, the "MTWin-5" function must be used to clear the "Utilites→Clear Transmission Lock" function. Subsequently, the data can be retransmitted.

The operating frequencies 125/134 kHz and 13.56 MHz are suitable for applications with low reading distances. If the transponder is only to be used for identification, a read-only transponder suffices. If data is to be stored in the transponder, a read-write transponder is necessary. The 125/134 kHz technique (LF) still distinguishes between read-only (read-only) and read-write transponders (chip has an additional data memory). This is historically, since the RFID development started with LF technology and these read-only chips were cheaper. At all other operating frequencies, there are now mostly read / write transponders.

The 125 kHz technique allows mobile devices to read distances up to 10 cm (depending on antenna and tag size.) Even if the transponder tags are attached to metal or embedded in it, automatic identification is possible Are, among other things, production control, object/goods identification in the metal environment, access control and animal identification.

13.56 MHz transponders enable the simultaneous reading of several transponders with their anti-collision technology. The range with mobile devices is however shorter than at 125/134 kHz and is max. Few centimeters. Areas of application are, inter alia, Production control, object/goods identification, access control, ticketing (e.g. public transport, events).

868-MHz tags (UHF) offer a high reading range of up to 10 meters, but the carrier material on which the tags are attached, as well as the contents of the packaging, have a great influence on the range. Areas of application are, inter alia, Production control with read distances greater than 2 meters, logistics, material flow (pallets etc.), object/goods identification (reusable and transport packaging).

Use the AT-120 utility. The AT-120 instruction manual contains the appropriate description.